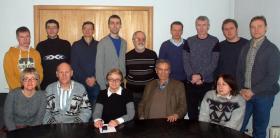

Top from left to right: Alexey Zotovich, Sergey Zyryanov, Dmitry Lopaev, Dmitry Voloshin, Konstantin Kopovsky, Alexander Palov, Yury Mankelevich, Konstantin Kurchikov, Alexander Chukalovsky; bottom from left to right: Olga Proshina, Alexander Kovalev, Tatiana Rakhimova, Alexander Rakhimov, Anna Vasilieva.

A scientific group leaded by Alexander Rakhimov carries out the research of the interactions between plasma and advanced electronics materials with ultra-low dielectric coefficient. We learnt the details of this study from the interview with the Leading researcher of the Department of Microelectronics SINP, PhD. Dmitry Lopaev.

- Dmitry, please, tell us about your activity in the group of Rakhimov.

- We study new nanoporous materials with low dielectric coefficient (so-called low-k films), which provide propagation of a signal in new chips with high-density packed elements - disctance between the elements is about 10-22 nanometers. The smaller this distance the more elements is possible to produce on one sq.cm. Now we are speaking about thousand of milliards of elements per sq.cm. This technology is used for production of computer processors and memory. Using of this technology means that we'll be able to displace powerful computation capacities on our hand.

- What is the porousity of the materials?

- It is up to 50%. It's like cheese with a lot of close holes. The size of a nanocavity varies from 2 up to 4 nm, i.e. several atom layers. Porous material is very light, more light than carbon-carbon composite material. It is twice more solid than quartz. It looks like fur hair or snow, but unlike snow you can't flatten it. It is firm, because it is adjacent. This material is extrudable.

- What is its density?

- The density of the advanced low-k dielectric materials is less than 1 gram per sq.cm.

- Who produce these materials?

- All materials are given by our foreign partners. In Russia there are no enterprises producing such materials. It is an organosilicate material consisting of silicon, oxygen, carbon and hydrogen. Therefore it is called SiOCH-material. It is the most non-conventional material.

- What is your input into the study?

- We started our studies over 6 years ago. The second generation of these materials has been already developed, and the basic purpose was to implement the technology of 22 nm, which is currently used for Intel processors of the last generation. They are solid-state drives (SSDs), terabyte discs with a size of your cell phone.

We study degradation of these materials in plasma under conditions of technological production process. I.e. we study degradation mechanisms during etching operation. This knowledge provides us possibility to avoid degradation.

- What have you learnt about degradation?

- The material is very porous. If even a small amount of water run into the pores, the material will absorb it as a sponge and its dielectic properties will not work. Indeed, water provides very strong polarizability and therefore dielectric coefficient will be very high. Therefore the material must be hydrophobic.

Hydrophobic properties are reached by means of CH3-methyl groups covering the internal surface of the pores. But unfortunately Si-СН3-groups are prone to chemical reactions with active particles - ions, radiacals, photons, which come to the film from plasma during the technological process. Therefore we have the following purposes: to understand what happens with Si-СН3-groups under influence of plasma; how to make them stable, because as soon as СН3-groups will be deleted from the material, water penetrates into the pores and degradation begins.

- And what is the solution?

- According to the principle from the film "The Caucasian captive": a person, who hinder us, will help us. We used this principle in our scientific research, it's found to be very vital.

- Please, tell us details.

- It was found out that hard photons produced by other type of plasma - noble Helium plasma, which are strongly absorded, modificate not only the surface, but also internal structure of SiO2 material. The top layer of the material compresses. If it is simultaneously bombarded by the ions which destroy links, than a solid but thin (only several nanometers thick) crust is formed. So we seal the material and degradation does not go, because nothing can penetrate into the material. We have shown it theoretically, and industrial engineers have already developed this technology.

But unfortunately it is impossible to avoid penetration of hard radiation into the film. We tried to cover it with the same layer from the top side, but it is so thin that radiation still penetrates and degradation goes even under this crust. Therefore we turned to cryogenic processes. It means that we freeze some products in the pores at temperature of minus 100 C and than form a structure. So we do not allow radicals or something else producing defects to penetrate there. Then we heat the material by subliming and delete these products from the pores. As a result you obtain required structure without injuring the adjoining section.

- What other types of material degradation go during the technological process?

- We need to pretreat the architecture of wiring layer. But pretreating radicals (as a rule it is made in fluorocarbon plasma) cause degradation: penetrating into the pores they remove methyl groups. As a result you obtain a structure, but after the pretreatment everything around it is damaged.

- What do you do in this case?

- There are several ways and currently we study how pretreating and degradation mechanisms work with fluor atoms.

- What diagnostic tests do you carry out?

- We have to carry out many types of complicated diagnostic testings: FTIR, RBS, XRF, XPS. For instance, XPS is study of the surface by means of radiation, when hard photons knock out electrons from the lower shells, and transitions from the higher shells provide information about the material's structure. Analysis of the energy provides high-precised information about connections between the atoms on the surface. I'd like to say that in order to carry out only one spectroscopic ellipsometry which has nanometer sensitivity, it is necessary to carry out a number of very complicated diagnostic tests. And it is very expensive to carry out them in other organizations. Each test costs several thousands of dollars.

MSU is one of few organizations in the world which is able to afford carrying out so complicated studies and producing of hundreds of samples. We perform advanced research, because we understand up-to-date plasma studies very good.

But nevertheless we'll not hit the development of specific problems, it is locked for us, because the technology is foreign. And it is necessary to organize our own development center, because without it we can't develop anything.

Intellectual property rights are ours. In future if we want to implement any technolgy in the case it is developed in Russia, we'll be able to use the results of our studies without any licenses.

Our group is one of few in Russia, who is specialized in the field of nanoporous materials studies. But we are only a small fragment. Russia needs a center with a number of analogous scientific groups specialized in several scientific fields, but they need to have some cube of clean rooms, where it would be possible to gather different technologies, not managers. It is necessary to gather different equipment, which I could rent from some foreign company. In this case it will be possible to develop something, and everything what we will develop, will be ours.